We put out central control unit problems

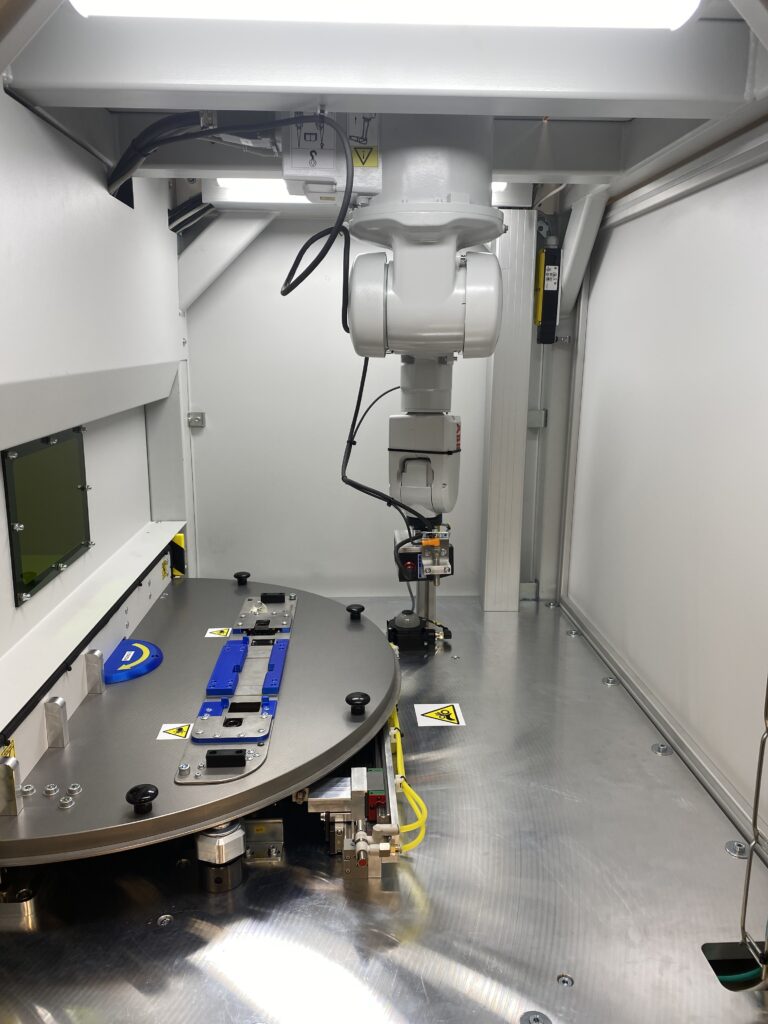

Last month, another EOL testing system left our production, which makes many of us feel a little safer again. This is a tester that is responsible for helping to deal with the exit inspection of fire safety equipment, which includes the detection of smoke, heat or life-threatening hazardous substance leaks.

Arming our facility with a solution that covers both optical and acoustic signalling testing was a challenge. At Kentigen, however, we are prepared for such challenges and routinely create solutions tailored to the customer's needs. As this is an important facility that can be found in many public places such as shopping centres, football stadiums or transport ships - the human factor in the issue of exit control is therefore not an option.

And how did the realization look like?

In the coverage of the requirements, the client bet on certainty. He approached our company again because he had already successfully cooperated with us on another project. Our client required a device for his new product line that would be reliable in terms of output control and functionality of the individual components tested, thus increasing the production of the production line.

Our solution offers:

- Optical measurement of LED luminosity using a camera in different product configurations

- Two microphones for measuring the acoustic expression of the alarm

- Operator-safe, impact-free chamber (soundproofing up to 100 dB)

- CSV reporting of the result to the database

- Connection to a database system for data collection in excel format

- Integration of barcode scanner, integration of OK and NOK label printers

- Test Sequence Control - Teststand

Our task was to check whether the tested components:

1) performs the function of a fire detector (light, sound) under specified conditions (pressure, temperature and humidity measurement)

2) communicates with detectors and then with the fire system, which further informs the IZS and PCO

Share this article

Download the article in pdf

Looking for a similar solution for your project? Contact us and we will get back to you to discuss the possibilities of cooperation.