The Run-In for the win!

Our RunIn tester solved the client's demands of component testing in various climatic conditions.

When there is a testing opportunity, there is Kentigen to grab it and excel at it. Testing the smart bars for one of our customers was the same case. Our client, a producer of components for the European automotive industry was looking for a solution how to test high-end smart bars (car infotainment units) in different conditions. Since the European automotive industry is a very demanding client with high standards, testing of the components is done in extreme conditions (extremely high or low temperatures).

Outsourcing is cheaper

In the beginning, our client wanted to solve component testing on their own in their factory, but that would have involved purchasing a climate chamber to simulate environmental conditions (temperature from −40 °C to + 250 °C, air humidity, etc.) and a device for simulating vibrations, the so-called shaker, and the subsequent assembly of their own test machine. However, this turned out to be too expensive of an investment and timeconsuming solution.

Therefore, the client decided to rent the climate chamber and shaker in an accredited laboratory and announced a tender for the development and assembly of the test machine. When choosing a new supplier, he determined three main evaluation priorities – price, production lead time, and technical requirements including a use of client's preferred components in the machine. Based on these requirements, the client chose our company to implement the solution.

After placing the order and fine-tuning the details with the client, we set about developing and assembling an automated Run-In testing machine for testing components, in this case specifically smart bars, in various climatic conditions.

Timeline of the implementation:

– Order for machine development: 10/2021

– Final documentation delivered from the customer: 03/2022

– Pilot run started: 05/2022

– Incorporation of all improvements and official launch of the machine: 06-07/2022

From machine development to successful smart bar testing

During the development of the machine, we had to overcome several technical challenges and face a whole series of new requirements that arose during the introduction of the machine into operation. The client's product is constantly being improved and has many sub-variants, which requires the control software of the test machine to be programmed as modularly as possible for easy modification of individual functionalities.

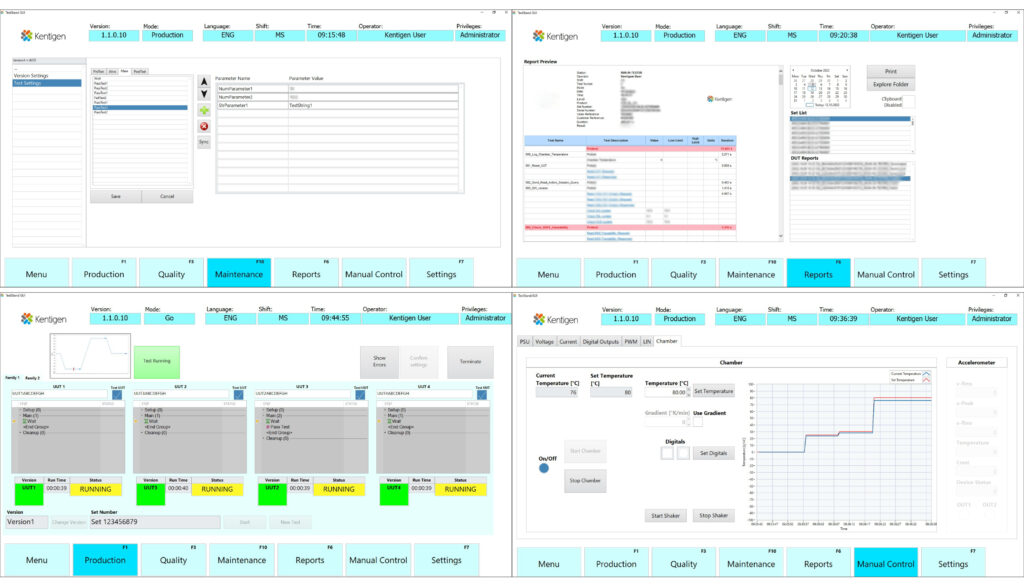

We also had to develop a software module for managing individual versions of smart bars using a database. For each version of the product that is stored in the database, it is possible to choose from the available test menu what is to be tested (e.g. a test for measuring the supply voltage from 8 V to 20 V for smart bar version A, for version B in the range from 9 V to 15 V, not to be performed for version C). We implemented a system for managing users and their access rights with the help of a database. Several levels of access rights are supported (operator, administrator, etc.). In addition to the name and password, in addition, the user can log in using an RFID chip. The main operation software also supports changing the GUI (visualization) language. Currently, English and Czech are supported, with the possibility of adding other languages. After incorporating all improvements, our client can fully benefit from the functionalities of the test machine.

The machine consists of a rack (testing and measuring machine) which is connected to a climate chamber. Products are being tested in the climate chamber - for example in temperature as high as 80 °C, as low as −30 °C, and all this accompanied by vibrations to test the components in extreme conditions.

Thanks to our machine, the client can test the manufactured smart bars and optimize the quality of the entire production process using the data obtained from the testing. In this way, the client will fulfill the environmental tests required by his customer and, in addition, ensure that the smart bars developed and manufactured by them have no or only very low scrumage and will continue to fulfill their function throughout the life of the car.

Engineered by David Karasek & Team

“Testing on the automated Run-In test machine improved our understanding of the behavioral aspects of the smart bars. As this is a new product (smart bar), we did not know how it behaves in extreme conditions. With this information, we are able to repeat the tests in a controlled manner as needed," customer´s repersentative says.