END OF LINE TESTING

Evolving automated tests is necessary part to have perfect electronic product.

In common practice, we use technologies for camera systems, industrial process control systems and test platforms. Together with their manufacturers, we therefore use their full potential and easily apply them directly to the architecture of the entire system.

Software loading of an infotainment unit

- Software loading of 24 units in parallel

- 10 GBit ethernet for high data throughput

- Fail safe functionality (independent system parts)

- IPC/PXI based variants

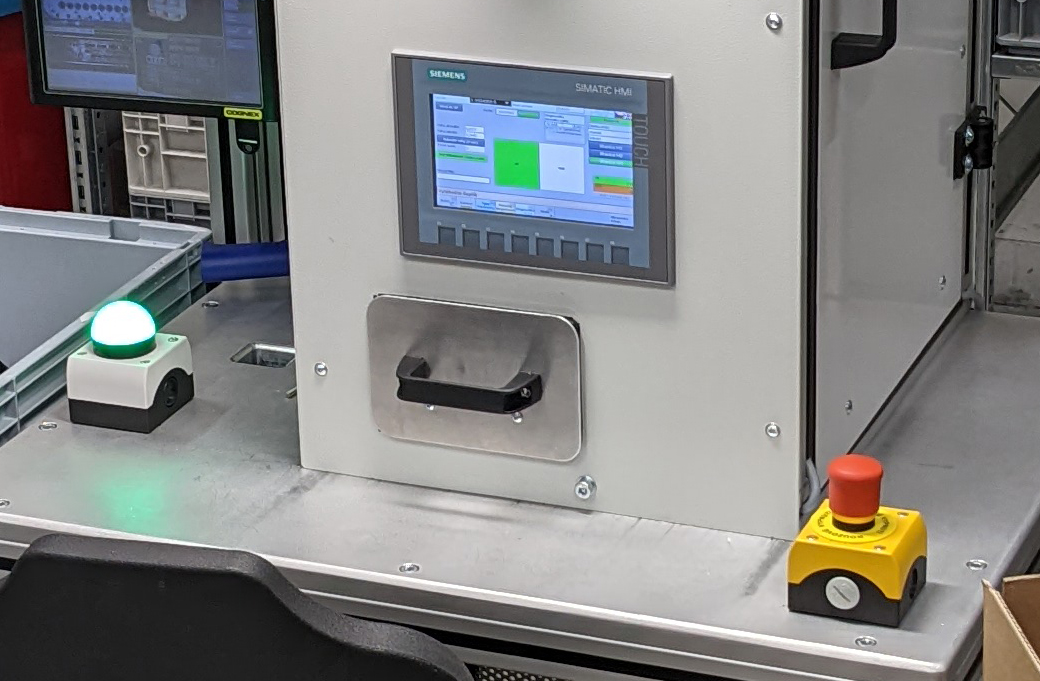

Audio connector (assembly + End of Line testing)

- Complete assembly and EOL of complex audio connectors for Automotive.

- 4 assembly stations with Vision inspections and final laser marking

- Cognex cameras used for check of correct color, position and presence

- Electric Scorpion for final laser marking

- Poka-yoke system design

- S7-1200 PLC system of each station with Pilz safety integration

FCT/EOL/TLC testing of telematic control unit

- Programming of up to 10 units in parallel

- Automated testing 4 – 10 units in parallel

- Testing RF / audio and electrical

- Cobot integration and communication via OPC UA

EV cable (Enf of Line testing)

- Operator operated station

- Manual turn-table with 2 positions

- MES data integration

- Presence inspections, part swapping avoidance

- Plastic housing correct assembly with damage detection and check of click of plastic locks

- BeckHoff PLC system with Sick safety integration

- 6 Cognex cameras for Vision inspection

BLDC ECU (End of Line testing)

- Testing of ECU for BLDC motor

- Keysight hardware architecture (Viper)

- NI TestStand test sequencer

Radio testing

- OPC UA and cobot integration

- RF tuning test

- Audio test

- Button test

ECU pro inteligent glass control (EOL)

- Isolation resistance measurement